How To Repair Fuel Sender Unit

Is your fuel gauge inaccurate? Is it no longer working at all? This is a common trouble on older boats, but is easy to fix. The get-go step is to determine whether the trouble is with the gauge or the sending unit. The test for this is straightforward. First, check that the gauge is receiving 12 volts of ability. Turn on the engine'due south ignition and probe with a multimeter between the ground and the positive terminal on the back of the gauge; it should exist marked with a "+" or an "I." If there is no voltage then the error is in the ignition excursion—and the gauge is probably practiced. If in that location are 12 volts at the estimate, either the sender, the guess or its wiring is the culprit, so you demand to proceed to the next step.

With power running to the gauge, disconnect the sending wire; it will be marked with an "S" at the back of the judge. Once the wire is disconnected, the guess should bound to its highest possible reading. If this is the example and then the approximate is practiced and you lot can proceed to the next footstep. If the gauge does not achieve its maximum reading, it is faulty and must be replaced.

Another test is to jump a wire or a screwdriver across the sending pivot to the footing pivot on the dorsum of the gauge. If there is no ground pin, use a longer wire and jump the sending pin to the engine cake. When y'all practice this, the gauge should become to its lowest reading. If it does, it is working properly.

If the gauge is good, the next stride is to check the other system components, as either the wire running to the sender or the sender itself must be faulty. To check the wire, disconnect information technology from both the sender and the "Due south" pivot on back of the guess. Set your multimeter to the Ohms scale and check the resistance within the wire. If there is no resistance (as shut to zilch Ohms equally possible), the excursion is good and the sender is faulty. In most cases, the sender and the fuel guess need to be matched to the resistance in the sender'south rheostat, and so to be completely sure you are getting accurate readings, replace both the sender and the gauge. Several companies provide pre-packaged "prepare-to-go" installation kits.

How Tank Sensors Work

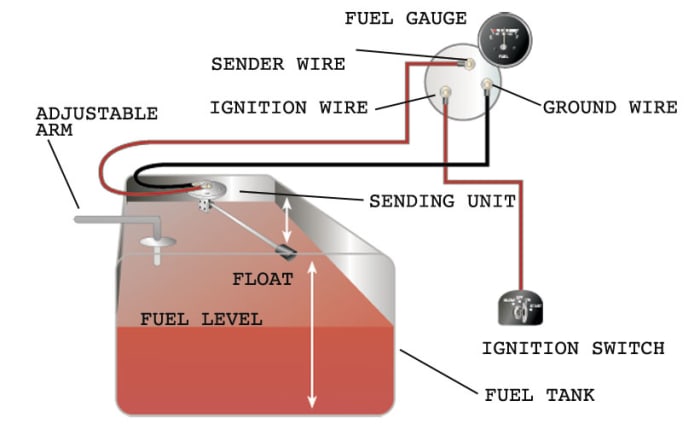

Nearly sensors have a mechanical floating arm and a rheostat. When the arm is all the way down, in the "empty" position, the resistance in the circuit to the gauge is near nada. Equally the arm rises, resistance in the excursion besides rises to around 200 Ohms. This resistance is what moves the needle on the gauge.

Often a problem occurs when the sending unit's floating arm becomes inoperative. On older units the floats may be fabricated of cork. Over fourth dimension these floats tin lose buoyancy or even sink birthday, causing the fuel gauge to indicate that the tank is constantly empty.

Another common trouble results when the rheostat doesn't transmit the correct electrical current to the fuel gauge, fifty-fifty though the floating arm is moving up and downwardly properly. In this example, both the sender and the gauge demand to exist replaced.

Left: My new sending unit installed. The sending wire leads off the center postal service; the other wire runs to ground. Note the marks I made to align spiral holes (dark) and the float arm inside the tank (in pencil).Correct: The new fuel gauge. The wire marked "+" runs to the engine's ignition switch. The center wire is basis; the 1 on the correct is the sending wire.

Sender Installation

Having obtained a new fuel sender kit, you lot should follow the directions specific to your new unit. In general, installation will involve the post-obit steps. Note that senders are not ordinarily "plug and play" units. The length of the sender arm may have to be modified to fit the dimensions of your fuel tank. This also ensures that the approximate reads properly.

Outset measure tank depth from the top of the tank, near the sending unit of measurement, to the bottom. This measurement determines the length of the sending unit's float arm. Side by side, trim the kit's sending unit arm—they normally come up in 24in lengths—and match it to the tank depth. A stiff pair of wire cutters volition work with almost units, but some require a hacksaw. Once y'all have cut the float arm to the correct length, fasten it with setscrews to the flange of the new sending unit that volition be screwed into the superlative of the tank.

The sending wire will come up off a post in the center of the flange. There may also be a ground wire coming off a 2d post at the border of the flange. Both wires lead to the back of the fuel gauge. Turn off the ability running to the gunkhole's systems before y'all disconnect any wires. And then disconnect both the sending wire and ground wire on the sometime sending unit of measurement. Note that if the gauge is grounded directly to a tab on the tank, there may be no basis wire. Remove the screws that agree the sending unit to the tank and take information technology out.

Side by side, remove the three wires on the back of the old gauge. I wire goes to the center pin on the tank sending unit, one goes to ground, and the 3rd connects to a 12-volt source, normally the ignition switch. Remove the fuel gauge.

Install the new sender by lowering the float and float arm into the tank. Be sure to slide a new gasket into place nether the flange, then align the gasket with the holes in the sender and in the tank. When the gasket is aligned, mark it in relation to the flange, as it may turn while yous are centering the screw holes to friction match the tank holes. Mark the screw holes in the tank for easier alignment; the flange will cover them and make them difficult to locate. Cheque to be certain the float arm can motility freely and volition not stick in a corner of the tank or against a vertical wall.

Orient the sender unit of measurement so the float arm's movement is not hindered. You tin check this ahead of fourth dimension by property the sender next to the tank before y'all install information technology to see which way the float tin move freely. Once you know the proper orientation, duplicate information technology when you lot put the unit of measurement in the tank. To minimize confusion, use a marking to show the direction of travel of the float arm one time the screw holes are aligned. Put in the new screws and tighten them down.

Fuel Gauge

Check the wiring diagram that comes with the kit and mark the dorsum of the new fuel judge with symbols for each post: "South" for the sender, "G" or "—" for the ground, and "I" for the ignition. Install the new gauge, reconnect the wiring and turn on the power. The fuel gauge should now show the right fuel level in the tank. To make sure the readings are authentic summit off the tank.

Troubleshooting

Problems often involve incorrect grounding and inadequate ability. If the gauge does not read at all, cheque the power with a multimeter at the gauge terminal. Test betwixt the positive terminal on the fuel gauge and a good ground; the reading should be 12 volts. If information technology isn't, check the ignition circuit. If that reads 12 volts, turn off the ignition. And then use the Ohm scale on your multimeter to check continuity between the ground terminal on the gauge and ground; the reading should be at or near zero Ohms. If not, recheck the footing excursion.

When everything is working properly, your new fuel gauge volition give yous a proper reading. Now you can relax, fifty-fifty if in that location is no wind, every bit yous will now know whether you take enough fuel for your fe genny to bear y'all domicile safely.

Resource

Vetus Maxwell, vetus.com

AB Marine, ab-marine.com

BEP Marine; bepmarine.com

Faria Marine Instruments, faria-instruments.com

Livorsi Marine, livorsi.com

Mirax Fuel Products, miraxfuelproducts.com

VDO,vdo.com

Westberg Manufacturing, westach.com

How To Repair Fuel Sender Unit,

Source: https://www.sailmagazine.com/diy/test-replace-fuel-gauge-sending-unit

Posted by: palmersquam1970.blogspot.com

0 Response to "How To Repair Fuel Sender Unit"

Post a Comment